|

|||||

|

|

| 泡沫铝内衬对抗内部爆炸钢筒变形的影响 | |

| 引用本文: | 程帅, 师莹菊, 殷文骏, 刘文祥, 唐仕英, 张德志. 泡沫铝内衬对抗内部爆炸钢筒变形的影响[J]. 爆炸与冲击, 2020, 40(7): 071406. doi: 10.11883/bzycj-2019-0339 |

| 作者姓名: | 程帅 师莹菊 殷文骏 刘文祥 唐仕英 张德志 |

| 作者单位: | 西北核技术研究院强动载与效应实验室,陕西 西安 710024 |

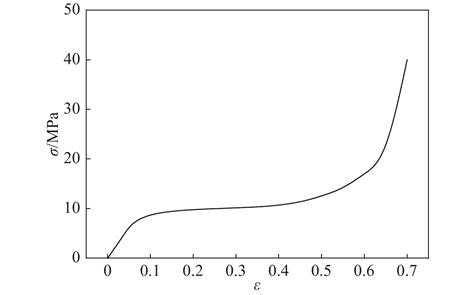

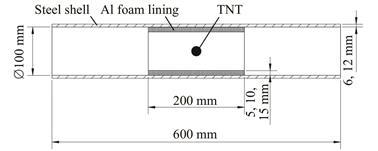

| 摘 要: |  为提高承受内部爆炸载荷钢筒的抗爆性能,研究了泡沫铝内衬对钢筒变形的影响。首先通过对比实验,发现在本文的实验条件下,泡沫铝内衬导致钢筒变形增大,甚至发生了严重的破坏;进而建立有限元模型,研究了钢筒变形随爆炸当量、泡沫铝内衬厚度的变化机理和规律。结果表明,添加足够厚度的泡沫铝内衬能够减小钢筒变形,但泡沫铝厚度不足时,则可能起到相反的效果。对于固定尺寸的含泡沫铝内衬钢筒,随着爆炸当量增加,泡沫铝内衬对钢筒塑性变形的影响主要包含3种模式。  |

| 关 键 词: | 爆炸容器 钢筒 泡沫铝 内衬 内部爆炸 |

| 收稿时间: | 2019-09-03 |

| 修稿时间: | 2020-05-13 |

| 点击此处可从《爆炸与冲击》浏览原始摘要信息 | |

| 点击此处可从《爆炸与冲击》下载全文 | |